When creating customized print and packaging solutions, every aspect must be carefully considered, analyzed and reviewed based on the perceived value it adds to the associated brand or product. Whether it’s a point-of-sale display, product packaging, high-impact direct mail or any other physical marketing tool, success is in the finer details.

Pressing the Limits

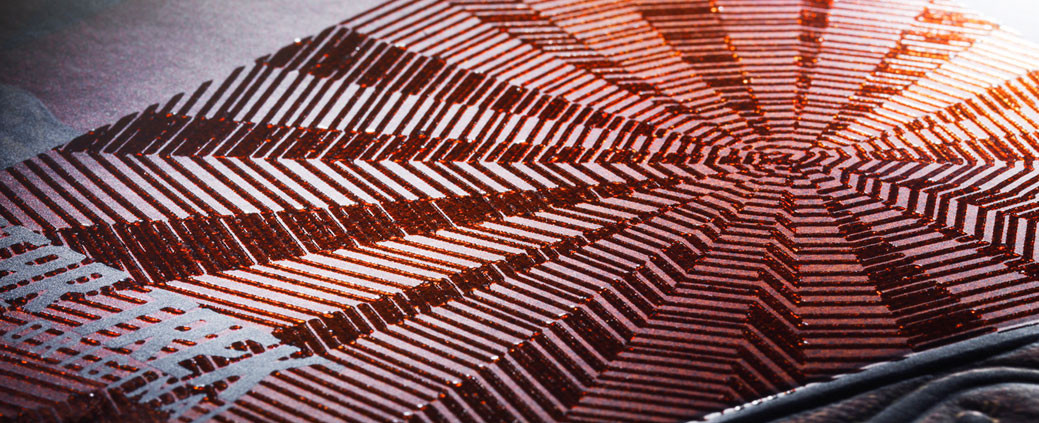

One of those finer details involves press and finishing effects. Does your marketing solution make a statement? You need your marketing tools to convey your brand’s value in a way that is familiar and enticing. While it may sound readily available, press and finishing effects are invaluable and should only be entrusted to a partner with the innovation and capabilities needed to take on the project. Here are a few details to consider when looking at a partner’s press and finishing capabilities:

- Machinery. When taking on press and finishing effects, it’s important to have the right machinery for the right job. Do they have access to the latest equipment such as a triple-coater UV and aqueous press? Do they have a robust line of in-house finishing equipment such as folder-gluers, foil stampers, embossing, die cutting and fulfillment? Do they have dedicated equipment for specific industries, such as health and beauty, entertainment or financial markets? Not all technology is created equal, and specific machinery produces specific results.

- Operator Creativity. It’s also pertinent that a packaging provider has experienced and creative operators to improve the job. This means possessing knowledge of, “How it works”, and “What needs to be done”. Operators are consultants to customers as well. Using a consultative approach allows operators to effectively utilize the physical machinery to its fullest capability. It ultimately comes down to whether the machinery is backed by creativity and innovation, or simply running through the motions.

- Operator Skill level. This level of creativity and innovation is determined by the skill level of the operator. Producing high quality press and finishing effects is as much about the machine as it is the human capital. Verify that they follow best practices for the use of their equipment.

Determining How to Proceed

If an appropriate partner with the right machinery, operator creativity, and operator skill level is selected, it ensures the project is off to the right start. From here, the process of determining which print and finishing effects to use begins.

- Brand style. When a creative team analyzes potential press and finishing effects for a product, package, or advertisement, it needs to fit with the brand style. For example, a company that focuses on selling accessories for outdoor activities that appeal to a rugged or nature aesthetic is probably shooting for a rustic image. Press and finishing effects that are glossy and flashy don’t represent the brand well. Instead, the creative team should look for textured effects that epitomize their value proposition.

- Call to action. What is the aim of the marketing tool? Depending on the call to action, the press and finishing effects may change. Everything from color and texture to shape and size are affected by the end goal.

A point-of-sale display or high-impact direct mail piece may be designed with the sole intention of attracting attention or engaging particular senses like sound, smell, or touch. Understanding the call to action can ensure the press and finishing effects allow for optimal receptivity.

- Competitive landscape. There is always a fine line to walk between mimicking the competition and overdoing differentiation. There is a reason most competitors offer similar packaging and design. It’s usually because market research suggests certain colors, shapes, sizes and placements. However, press and finishing effects can provide healthy differentiation by altering the perception of the norm. Is there a way to set your brand apart from the competition without overdoing it and risk turning consumers off from selecting your product?

- Sales channel. Where is the product being sold? Whether it’s purchased through an e-commerce site, point-of-sale display, event booth, retail shelf, or other type of sales channel, determine the type of finishing effects needed to effectively get your product noticed. Items sold online are much less dependent on being multisensory. Instead, the majority of the focus is on developing a finish that is visually pleasing and encourages repurchasing behaviors in the future.

Being Guided through the Print and Finishing Process

It’s far more complicated than simply coming up with an idea and producing it. There are multiple stages of revisions, testing, and even market analysis. After determining which print and finishing effects to use, the process really begins. It’s then up to the machinery and operators to oversee the process with careful attention to detail.

The Finishing Touch

At JohnsByrne, we specialize in producing high-quality press and finishing effects. We carefully consider the unique needs of our clients and work to deliver creative solutions through the use of cutting edge technologies. For more information, contact us today.

More Resources

Related Posts

As a leading provider of premium packaging and custom print solutions to the Beauty & Wellness, Spirits, Financial Services, Consumer Products and Entertainment markets, JohnsByrne … Elevating Brands Through Advanced Digital Enhancement

JohnsByrne is pleased to announce that we’ve received an impressive seven awards in the categories of Innovation and Sustainability at the 80th Anniversary of the … Unboxing Award-Winning Innovative & Sustainable Packaging

Standing out in today’s competitive market is vital to keeping your brand alive – no matter what industry you’re in. Since packaging is the first … Lenticular Printing