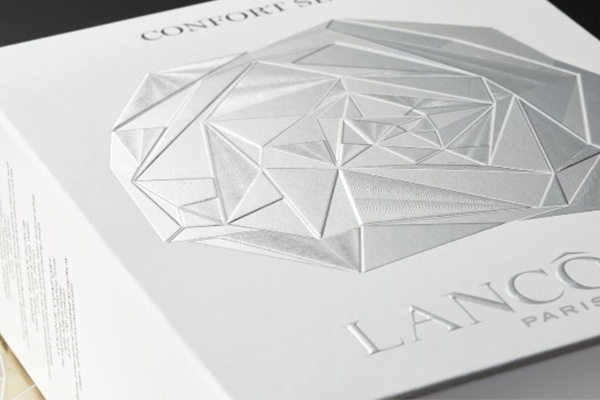

Innovative structures

Our knowledgeable and diverse structural design team works directly with our customers to understand their brand direction, product vision, and their desired high-impact result. They always begin by designing with the end in mind: integrating intended use, sustainability, functionality consumer preferences and current market trends (among many others) in intentional package design.

More on Structural DesignDecorative solutions

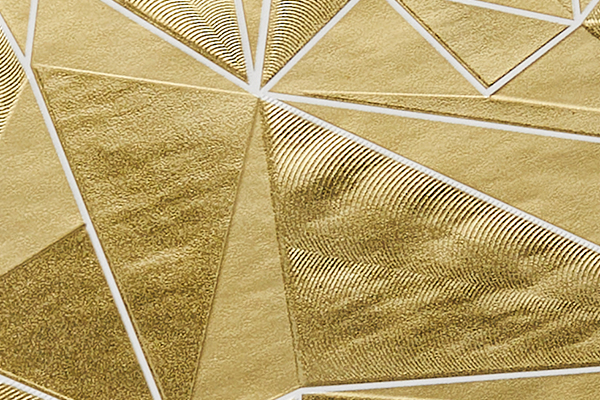

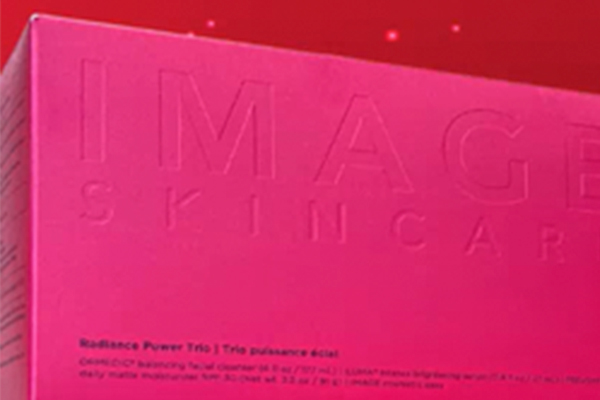

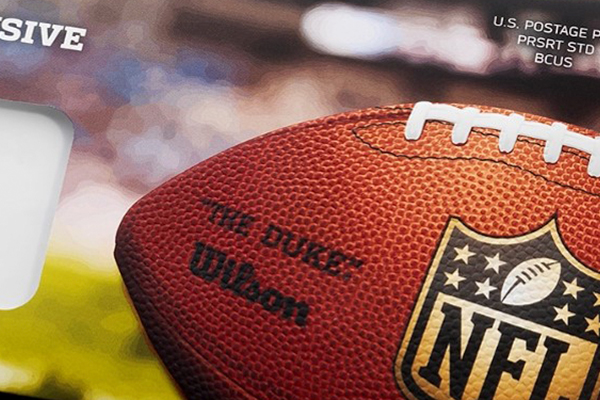

Our robust finishing capabilities include folding-gluing, die-cutting, embossing-debossing and highly sophisticated foil stamping. We combine the latest finishing equipment with decades of experience and best practices to create mesmerizing finishing effects that innovate and boost the appeal of your products. Watch the overview video of our decorative solutions.

Cast & Cure

Die Cutting

Double Dimension

EmoteCoat

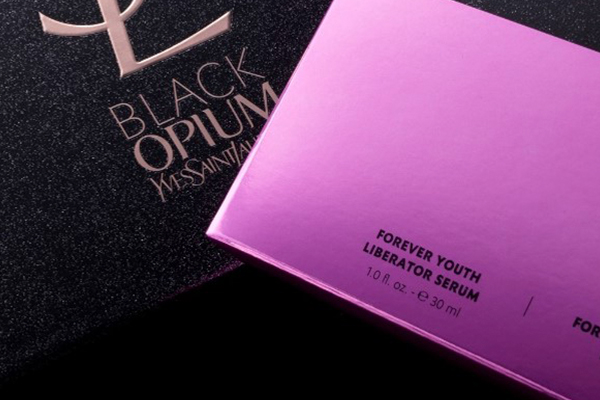

Glitter

Grit / Sand Coating

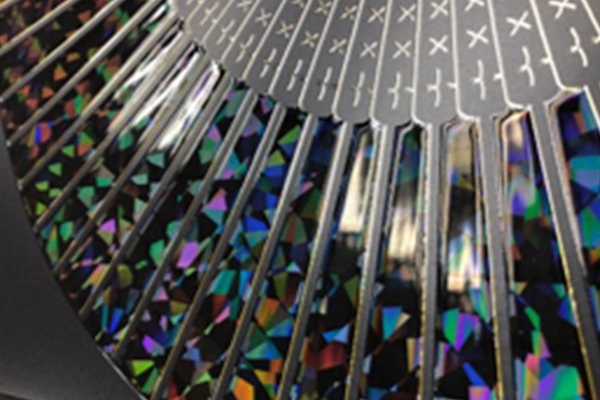

Holographic

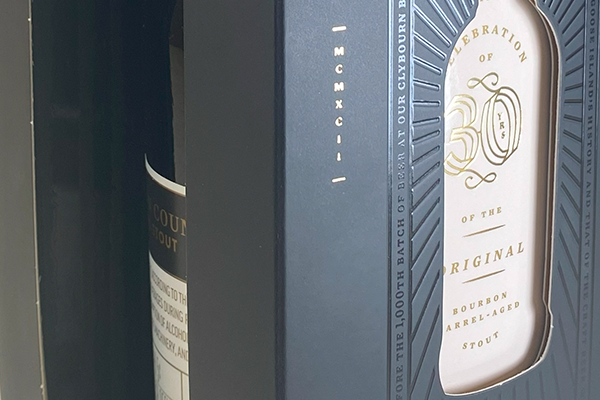

Hot / Cold Foil

Metallic Sheen

Microetching

On-Press Deboss

Pearlescent/Iriodin Coating

Post-Press Emboss

Reticulating

Scent

Soft Touch

UV/Tactile Coatings

Variable Foil

Sustainable packaging

Our goal at JohnsByrne is to assist our customers along the path to a more sustainable package and to help you meet your sustainable packaging goals. This includes optimizing structures, accelerating the move away from plastics and the increased use of sustainable and recycled paperboard.

More on Sustainable Packaging