Finishing touches and convenient shipping options

JohnsByrne has the capability to complete a project from beginning to end. To finalize your packaging project, we provide the additional assembly solutions you need, such as:

- Mounting

- Film laminating

- Overwrapping

- Window patching

- Inserting

- Kitting & pack out

JohnsByrne can offer the total assembly solution to ensure your end product is ready to ship to your destination. Our shipping and fulfillment team can make sure your packaging arrives exactly when it’s needed—even for same-day delivery or drop shipping.

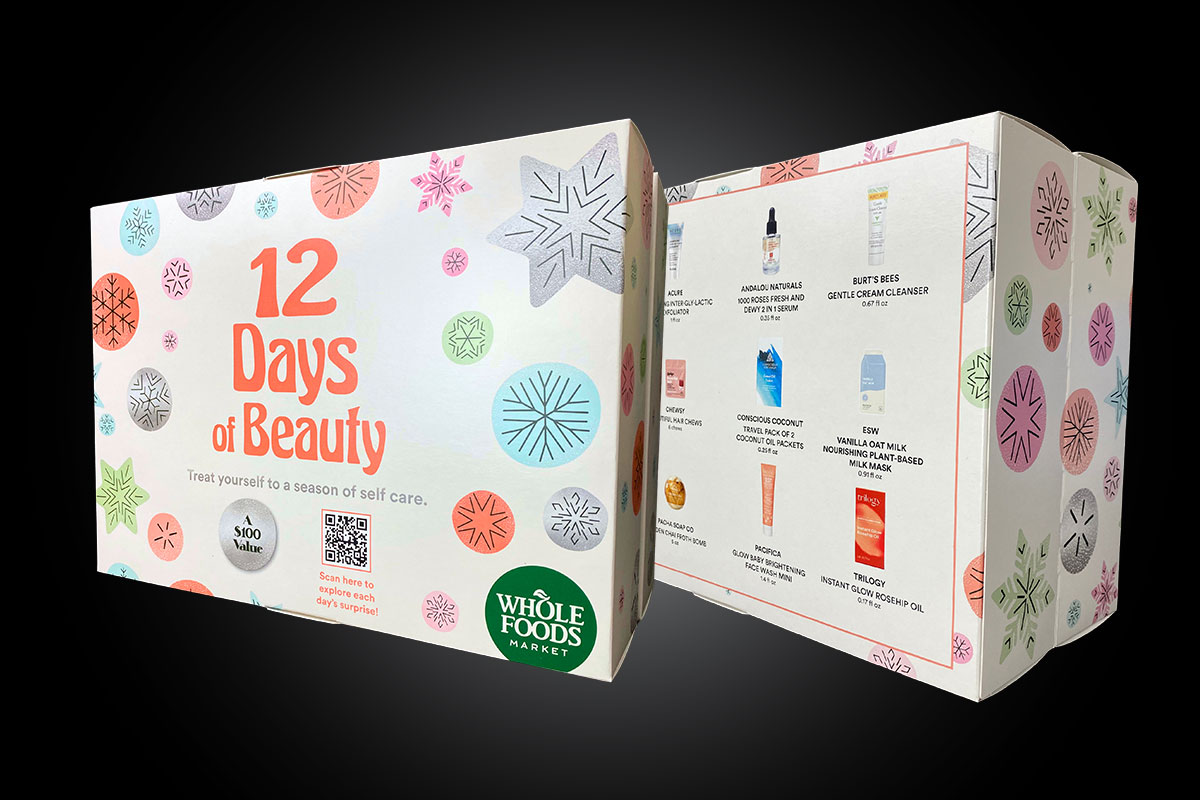

Recent Work View Gallery of Work

Scalable for long or short runs

We have the ability, space and manufacturing flexibility to scale to as many assembly lines necessary for your long or short run projects. We provide complete assembly for a variety of packaging materials and kits, including:

- Packets

- Sales kits

- Welcome kits

- Customized kits

- Launch kits

Secure facility

Our extensive policies, procedures and surveillance ensure that the production of your products remains secure. This involves IT, building, product and employees for a comprehensive solution to IP protection.

- Controlled building and department access

- Employees ID key card badges and visitor policy

- 24 / 7 Surveillance including a 360-degree view camera system throughout the building

- No phone / camera usage allowed in plant

- Employee background checks and signed NDAs

- IT and security policy encompassing confidential data

- Digital asset and electronic prepress procedures for files covering backup and system removal

- Secure product SOPs and chain of custody for material including all components (files, plates, material, production, shipping, material destruction and reconciliation)

- Secured Material Storage Area (SMSA) with added control and restricted access