This is simple: it’s not just a box. Every product deserves packaging that is both practical and exceptionally appealing. It should be structurally conceived so products are protected, displayed, and logistically cost-effective. It should also be visually conceived so consumers—whether online or in-store—are captivated, informed, and motivated to purchase—and then to purchase again.

And that, all in all, is more complex.

Regardless of category, the route to custom product packaging that delivers on all those promises runs right through “The Limitless Pressroom” at JohnsByrne. Our teams of imaginative engineers, designers, press operators, and staff have become innovative thought leaders in the industry. Every project, no matter the client or budget, is 100% custom.

Now, you might consider a press room something other than a laboratory. But 65 years of experience proves that true innovation – combining art and technology to create stunning, multisensory brand experiences for consumers – only comes through imagining and manipulating unique coating sequences, printing, and drying to create never-before-seen custom product packaging. Over the decades, we’ve conducted the lion’s share of chemistry experiments, engineering brainstorms, and even around-the-world sourcing searches for unique materials, all to say “yes” to customers when others have said “no.”

Take the leading collectible sports card manufacturer, which years ago wanted to print baseball cards on real wood. Could we print wood cards that mimic a wooden baseball bat?

At that point, no one had. At this point, we uncovered a particular type of African ashwood, imported it, and started experimenting. It was apparent that fragile wood curled on the press, but we discovered laminations of 16pt wood and 14pt backer board could go on successfully in 28×40 sheets printed, stamped, and numbered on the back. A second series was to follow along with collectible cards stamped out of leather embedded with actual team jersey fragments and cards with mylar inserts that looked like 35mm slides. You could project them on-screen.

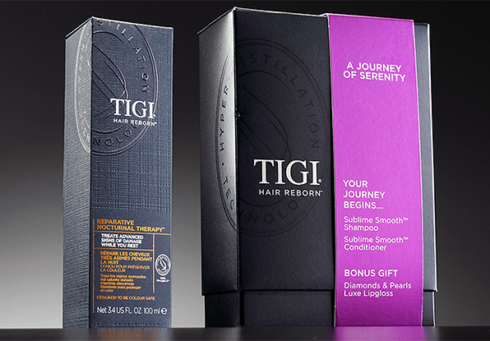

Unique products deserve unique packaging

Fast forward a couple of decades. Nobody would be insane enough to do it that way with today’s technology; you’d simply simulate wood via specialty coatings on-press.

And we do, of course. It’s called adding value – and elevating brand value: utilizing JohnsByrne’s singular press technologies to create never-before-seen custom packaging out of coatings and paper, printed and finished all in one pass, all on one line.

For luxury brand CASAMIGOS Tequila (co-founded by George Clooney and Rande Gerber), it was a gift box for three flavors of their “best-tasting, smoothest tequila around.” After developing cost-effective options and refining the details, the first step was pre-foil stamping silver foil to each sheet.

These sheets were fed into our truly unique Press384, with its 15 units and signature in-line, one-pass technology. Four colors were printed, plus three PMS spot colors. Soft-touch matte coating went down on the first coater, while varnish went down in the eighth print unit. The final coating unit applied spot UV coating. An entire sequence took place in just one pass through the press.

Next came foil stamping and the emboss-deboss technique, which created the wood grain pattern: tactile peaks and valleys that would engage the consumer’s sense of touch. Finally, they went for die-cut, fold, glue, and shipping.

We know that you know what sets your brand apart. We focus on working with you to develop packaging that highlights those differences, with a multi-sensory impact that impresses the consumer from the moment they connect with your product.

Custom packaging solutions that protect your products

Remarkable visual effects, classic designs, stunning simplicity, and cutting-edge approaches for product display are only the beginning of what emerges from JohnsByrne’s Limitless Pressroom.

Every custom packaging solution must keep products intact and satisfy consumers. That’s paramount. That means package designs must withstand packing, shipping, unpacking and rough handling. Again, JohnsByrne’s depth of experience assures that custom package designs will comply with (if not exceed) industry standards and that our innovative, multi-disciplinary teams will always address client-specific concerns. Every design, every manufacturing process, and every innovation is rigorously tested and validated such that the project can be effectively modified at any point to resolve any specific concern.

One key is selecting packaging materials best suited to the products in question. Choosing the suitable materials is a primary aspect of ensuring structural integrity, not to mention the visual appeal of the final packaging product. Different paper and plastic substrates, or combinations of both, bring their unique benefits to bear, and every JohnsByrne packaging solution is designed to inspire purchase and create lasting brand love while reducing the chance of product damage and returns.

Custom luxury packaging by JohnsByrne

The perception of “luxury” can really move any widely used product to a higher echelon of quality in consumers’ minds. To achieve such a desirable outcome, luxury packaging must challenge every aspect of custom package design: shape, size, use of inserts, stock choices, and printing effects.

The problem is that many materials that speak “luxury” to the consumer also speak “cost-prohibitive” in mass production. Let’s face it: Printing on luxury packaging materials such as silk and leather may kill it from the perceived value and branding side, but it may also kill your procurement and purchasing departments’ budgets. What to do?

Again, JohnsByrne’s historical ability and willingness to take risks and do what competitors said we couldn’t with current technology allow us to mimic many luxury materials with innovative yet reasonably priced solutions. For example:

Silk

In the first step, an Iriodin coating produces a shiny, smooth texture. Together with other finishes (such as embossing), it is a perfect path to a silk-like finish that speaks of subtle elegance.

Stone

Mimicking the aesthetic of stone – and achieving the look and feel almost perfectly – can be achieved by the artistic application of coarse reticulation varnishes or grit coatings.

Leather

Soft touch and debossing patterns are ideal to mimic the look and feel of leather with remarkable realism.

Linen

Printing on actual linen is a tall order like silk, stone, and leather. To create the feeling of linen, however, we can apply textured embossed patterns with muted colors and soft touch coatings.

Wood Textures

The feel and warmth of wood can be replicated through embossing, realistic artwork and reticulating varnish.

Along with substrates, specialty printing techniques can take custom luxury packaging designs to the next level. The careful merging of substrate and custom finish results in a visual punch and a multi-sensory package-opening experience, bolstering the perception of exclusivity and superior quality in the consumer’s eye and heart.

Every day, we find ways to add value and elevate the brand. And it needn’t be outrageous to deliver outrageously good brand impact. Our portfolio gallery offers a host of examples of innovative custom packaging concepts and luxury packaging executions that pressed the limits of client satisfaction, performance, and innovation to bring these products to life. Let’s talk to see how we can bring your unique packaging to life.

Related Posts

When it comes to creating standout packaging, the folding and gluing process is the unsung hero that transforms flat, printed materials into eye-catching, functional packages. … Fast 5 Facts: Folding and Gluing: Bringing Packaging to Life!

In today’s competitive market, packaging does more than just protect a product; it tells a story, engages the senses, and leaves a lasting impression on … 20 Premium Packaging Finishes: A Guide to Elevating Your Brand Experience

As a leading provider of premium packaging and custom print solutions to the Beauty & Wellness, Spirits, Financial Services, Consumer Products and Entertainment markets, JohnsByrne … Elevating Brands Through Advanced Digital Enhancement